Advanced moulding techniques, a variety of decorative options and a first-rate facilities keep Sunrise Plastic products a cut above the competition

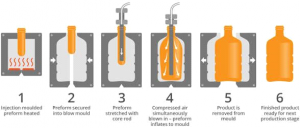

Injection Stretch blow Moulding

Injection Stretch Blow Moulding is the process of manufacturing high quality and very high clarity bottles. The plastic is melted and then injected into a mould to form a preform. The preform is then preheated before being held inside two halves of a mould. When the preform is in the mould, it is theninflated using high pressured air while simultaneously being stretched. This method is often used to increase the strength of the wall of the bottles which contain carbonated drinks.

Injection blow Moulding Overview

Dominance Of ISBM

- Excellent clarity, nearing that of glass

- Lighter weight bottles can be made

- High breakage resistance

- Dimensionally accuracy

- Thermally stable

An Injection Moulded Preform

![]()

- One-stage PET processing is extremely versatile because the same machine can be used to make a wide variety of bottles and jars in all shapes and sizes.

- Two-stage PET processing includes making preforms by Injection Moulding & blowing bottles by Stretch Blow Moulding.

The Edge Of PET Moulding

- Clear & transparent

- Lightweight

- No Leakage

- Suited for various forms of decoration including, printing ,sleeving and labelling

- Design Flexibility

- 100% Recyclable

- It has good barrier properties