Advanced moulding techniques, a variety of decorative options and a first-rate facilities keep Sunrise Plastic products a cut above the competition

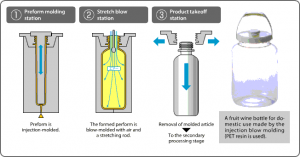

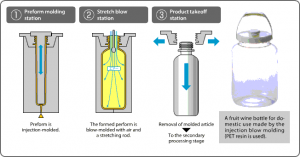

Injection blow Moulding

IBM is used for the production of hollow objects on a mass scale. The main applications are bottles, jars & other containers. The IBM process produces bottles of a superior visual and dimensional quality as compared to Extrusion Blow Moulding.

Injection blow Moulding Overview

Common Products For Injection Blow Molding

- Jars, Bottles

- Ovals, Cylinders & Boston Rounds

- Pill Bottles

- Roll-on Deodorants

- eye droppers

Advantages Of Injection Blow Moulding

- high dimensional accuracy

- Cost efficient

- Mass scale production

- Injection moulded neck

- Saves resources

- No scrap

- low weight fluctuation

- Good material distribution consistency

- High cavitation capability with smaller bottle sizes