Advanced moulding techniques, a variety of decorative options and a first-rate facilities keep Sunrise Plastic products a cut above the competition

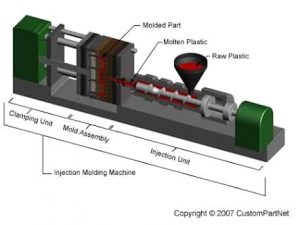

Injection Moulding is the most commonly used manufacturing process for the fabrication of plastic products. A wide variety of goods are manufactured, which vary greatly in size, complexity and application. It requires the use of an injection moulding machine, raw plastic material and a mould. The plastic is melted in the injection moulding machine and then injected into the mould, where it cools and solidifies into the final product.